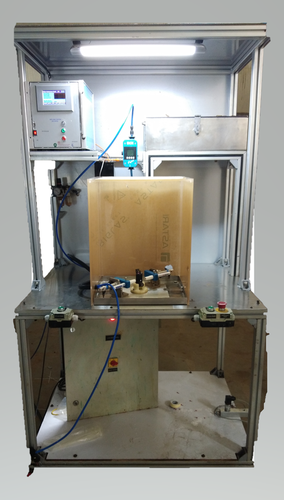

Leakage Testing Machine for Axle

Leakage Testing Machine for Axle Specification

- Dimension (L*W*H)

- 230 x 280 x 750 Millimeter (mm)

- Material

- Stainless Steel

- Product Type

- Leakage Testing Machine for Axle

- Usage

- Industrial

- Operate Method

- Automatic

- Power Supply

- electric

Leakage Testing Machine for Axle Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, South America, Asia, Central America, Africa

- Main Domestic Market

- All India

About Leakage Testing Machine for Axle

- Highly accurate dependable

- Quick leak detection

- Multichannel operation

- Smart pneumatic electronic circuits

- Easy calibration through Leak Masters

- PC Interface through RS 232 C

- Pressure Decay leak measurements

- Strain gauge based pressure transducers transmitters

- Theory of working

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Leakage Testing Machines Category

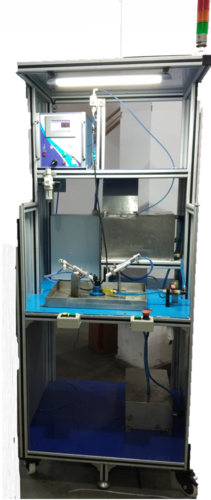

Motor Performance & Leakage Testing Machine

Price 140000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mixed

Voltage : 220 Volt (v)

Product Type : Auto / Manual

Power : 220 Watt (w)

Fabric Pasting Machine

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mixed

Voltage : 220 VAC Volt (v)

Product Type : Special Purpose Machine

Power : 220 V AC Volt (v)

Soldering / Sequence Panel

Price 67000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Aluminium

Voltage : 220 Volt (v)

Power : 220 Watt (w)

Flow and Motor Performance Testing Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Voltage : Mains 220 V AC, 50 Hz, 10% Internal 24 V DC4.5 amps, 5 V DC3 amps, 12 V DC1 amps Volt (v)

Product Type : Flow and Motor Performance Testing Machine

Send Inquiry

Send Inquiry Send SMS

Send SMS